Angular Ball Joint Assembly is manufactured from EN1A / EN1A(L)/ EN8 / S.S.303. It is widely used for transmitting linear motion to angular displacement or rotational motion. It is mainly used in automobile industry as cable ends (as fuel injection system, wiper arm blades) in vehicles like trucks, trailers, tractors, earth moving equipments and excavators for road and construction. It is also widely used in textile machinery and machine tools for vertical to angular displacement.

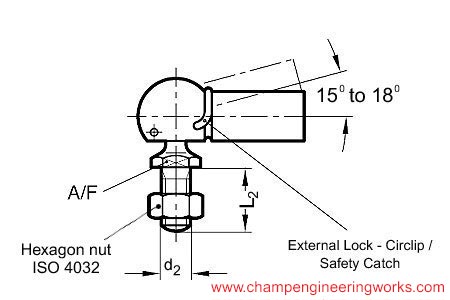

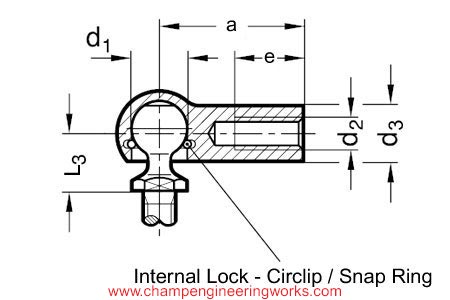

Angular ball joint assembly is manufactured as per DIN 71802 standard from ballend socket bore dia 8mm to 19mm with different combination of thread sizes M5x0.8 to M14x2 and as per customer requirement on ballend socket and ballpin stud. Intensive dimensional check is maintained at every stage of manufacturing till final stage of assembly and fitting with internal lock / snap ring and external lock / safety catch for positive locking. High grade automotive grease is used in final assembly to withstand high temperature and pressure in continuous movement of the assembly.